Parallel vs. Sequential Twin Turbo: What’s the Real Difference?

Parallel vs. Sequential Twin Turbo: What’s the Real Difference?

Image: Parallel vs. Sequential Twin Turbo: What’s the Real Difference? – Performance Comparison and Specifications

If you’ve ever stood by a turbo‑petrol beast humming at the line, you’ve probably wondered why some engines use two turbos in parallel while others stack them sequentially. Both designs aim to squeeze more air, more power, and more excitement out of the same displacement, but they do it in very different ways. In this guide we’ll break down the anatomy, performance traits, and real‑world applications of parallel and sequential twin‑turbo setups so you can decide which philosophy fits your driving style.

What Is a Twin‑Turbo System?

A twin‑turbo system simply means an engine is equipped with two turbochargers instead of one. The idea is to increase airflow without making a single turbo gigantic – which would introduce lag and stress. By splitting the work between two smaller units, manufacturers can harvest the best of both worlds: quick spool‑up and high‑end power.

Parallel Twin Turbo Explained

In a parallel configuration each turbo receives exhaust gases from its own set of cylinders (usually half the engine). Think of a V‑engine where the left bank feeds Turbo A and the right bank feeds Turbo B. Both turbos spin at roughly the same speed and feed a common intercooler before the compressed air merges into the intake manifold.

Key Characteristics

- Symmetrical airflow: Both sides of the engine get the same boost pressure.

- Immediate response: Smaller turbos spin quickly, delivering strong low‑end torque.

- Simple plumbing: Fewer wastegates and bypass valves mean less complexity.

Popular examples include the Nissan GT‑R’s VR38DETT and the Porsche 911 Turbo’s twin‑turbo flat‑six. Both rely on parallel turbos to give a linear power curve that feels natural on the road.

Sequential Twin Turbo Explained

Sequential systems take a two‑stage approach. One smaller turbo works alone at low engine speeds, providing instant boost and minimal lag. As RPM climbs, a second, larger turbo kicks in, taking over or adding to the boost pressure. This arrangement can be found on engines that need a broad torque band while still delivering high‑end horsepower.

Key Characteristics

- Two‑stage boost: Small turbo for low‑end, big turbo for high‑end.

- Complex control: Requires sophisticated wastegate and bypass valve sequencing.

- Optimized efficiency: The engine can stay in its most efficient boost zone longer.

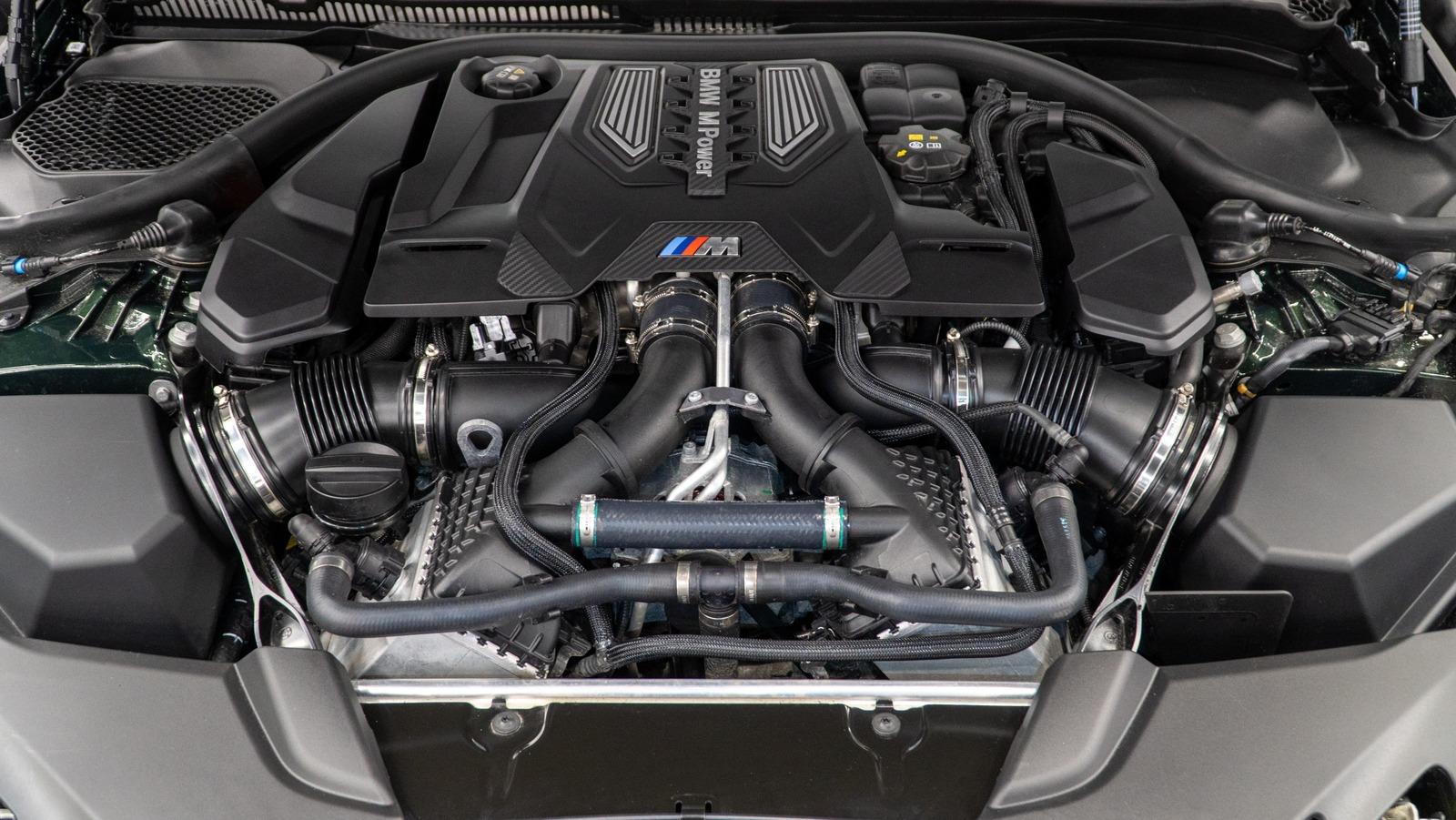

The classic example is the BMW M5 (S63) V8, which uses a sequential twin‑turbo to deliver a flat torque curve from 1,500 rpm all the way to 6,500 rpm. The result is a seamless surge that feels like a single, massive turbo without the lag.

Design & Dimensions

| Aspect | Parallel Turbo | Sequential Turbo |

|---|---|---|

| Turbo Size | Two small‑to‑medium units | One small + one large unit |

| Exhaust Manifold | Split (two‑way) | Single‑stage (low) → dual‑stage (high) |

| Intercooler Layout | Single shared | Often dual, one per stage |

| Packaging Space | Wider, shorter | Longer, may need extra space |

Feature Comparison

| Feature | Parallel | Sequential |

|---|---|---|

| Turbo Lag | Low to moderate | Very low at low RPM, moderate at transition |

| Power Band | Broad, linear | Extremely wide, flat torque |

| Complexity | Simple | High – requires advanced ECU control |

| Maintenance | Easy, fewer valves | More frequent checks on wastegates |

Engine Specifications (Typical Examples)

| Model | Layout | Boost Pressure | Peak Power |

|---|---|---|---|

| Nissan GT‑R (VR38DETT) | Parallel twin‑turbo V6 | 1.8 bar | 600 hp |

| BMW M5 (S63) | Sequential twin‑turbo V8 | 2.0 bar | 600 hp |

| Porsche 911 Turbo (991.2) | Parallel twin‑turbo flat‑6 | 1.9 bar | 572 hp |

| Audi RS7 (C7) | Sequential twin‑turbo V8 | 2.1 bar | 560 hp |

Price Comparison

| Setup | Base Cost (USD) | Additional Parts | Total Approx. |

|---|---|---|---|

| Parallel Twin Turbo | $3,200 | Intercooler, wastegate | $4,500 |

| Sequential Twin Turbo | $4,500 | Dual wastegates, extra ECU mapping | $7,200 |

| Aftermarket Upgrade (parallel) | $5,000 | Full bolt‑on kit | $8,000 |

| Aftermarket Upgrade (sequential) | $7,500 | Custom plumbing, tuning | $12,000 |

Pros & Cons at a Glance

Parallel Twin Turbo

- Pros: Simple design, quick spool, reliable.

- Cons: May hit a “boost wall” at very high RPM, limited ultimate power.

Sequential Twin Turbo

- Pros: Near‑instant low‑end torque plus top‑end horsepower, excellent for performance cars that need a flat torque curve.

- Cons: Complex plumbing, higher cost, more demanding on maintenance.

Real‑World Applications

When manufacturers choose a twin‑turbo layout, they consider the vehicle’s intended use.

- Sports cars like the GT‑R or 911 Turbo favor parallel setups for a linear, driver‑focused feel.

- Luxury performance sedans such as the M5 or RS7 opt for sequential systems to deliver effortless acceleration from a stop to red‑line.

- Hybrid‑turbo combos (e.g., Mercedes-AMG EQS) sometimes blend both philosophies with electric assist, but the core turbo architecture still follows one of the two paths.

Choosing the Right Setup for You

If you spend most of your time on the track, a parallel twin‑turbo’s predictability can be a confidence booster. On the other hand, if you want a daily driver that feels like a rocket at any speed, the sequential layout’s seamless torque delivery is hard to beat. Consider also the long‑term costs – a sequential system may require more frequent valve checks and a tuned ECU, which can add up over years of ownership.

Conclusion

Both parallel and sequential twin‑turbo systems have earned their place in modern performance engineering. Parallel turbos give you a straightforward, fast‑spooling package that’s easy to maintain, while sequential turbos push the envelope of torque flatness and high‑end power at the expense of complexity and price. Understanding the trade‑offs helps you pick the right turbo philosophy for your driving goals, whether you’re chasing lap times, cruising on the highway, or simply love the sound of a turbo‑charged engine humming under the hood.

FAQ

- What is the main difference between parallel and sequential twin turbos?

- Parallel turbos run side‑by‑side and boost the engine simultaneously, whereas sequential turbos use a small turbo for low RPM and bring in a larger turbo as engine speed rises.

- Which setup offers less turbo lag?

- Both aim to reduce lag, but sequential systems provide the lowest lag at low RPM because the small turbo spins almost instantly.

- Are sequential turbo systems more expensive?

- Yes, they require additional wastegates, bypass valves, and sophisticated ECU mapping, which raises both parts and labor costs.

- Can I retrofit a parallel turbo setup onto a sequential engine?

- It’s technically possible but not recommended without a full redesign of the exhaust manifold and ECU calibration.

- Do parallel turbos affect fuel efficiency?

- They can be slightly less efficient at high boost because each turbo works harder, but modern engine management mitigates the difference.

- Which cars use sequential twin turbos?

- Examples include the BMW M5, Audi RS7, and some Mercedes-AMG models.

- Which cars use parallel twin turbos?

- Notable models are the Nissan GT‑R, Porsche 911 Turbo, and the latest Subaru WRX STI.

- Do twin‑turbo setups work with ADAS features?

- Yes, modern ADAS systems are calibrated to account for the power delivery of both turbo types.

- Is maintenance more intensive on sequential turbos?

- Generally, yes – the extra wastegates and valves mean more components that can wear out.

- Where can I learn more about twin‑turbo technology?

- Check out in‑depth articles like TurboSmart’s Parallel vs. Sequential Twin Turbo guide for technical details and real‑world testing data.