Bottom Line Up Front

Cars are built with welding because it’s faster, cheaper, and stronger for the way vehicles are used, while planes stick with rivets to handle high‑altitude stresses and easy field repairs.

Why Cars Use Welds Instead of Rivets (And Planes Still Prefer Rivets)

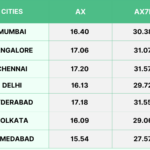

Image: Why Cars Use Welds Instead of Rivets (And Planes Still Prefer Rivets) – Performance Comparison and Specifications

Design & Construction

In an aircraft, every joint must survive vibration, temperature swings, and pressure changes at 30,000 feet. Rivets create a “clamp” that distributes load across a larger area, which is ideal for thin aluminum skins. They also let mechanics replace a damaged panel without disassembling the whole structure.

Cars, on the other hand, have a chassis made of thick steel or high‑strength aluminum. Welding fuses metal edge‑to‑edge, creating a bond that’s as strong as the base material. For a sedan that experiences road bumps and crash forces, a welded joint offers higher stiffness and lower weight compared to a riveted one.

Performance & Durability

Welds can be inspected with simple visual checks or ultrasonic tools, and they don’t add the extra weight of rivet heads. That helps fuel economy and handling. Rivets add a few extra pounds, which matters a lot in aviation where every ounce influences lift and fuel burn.

Repairing a welded car frame usually requires cutting and re‑welding, which is quick in a shop with modern equipment. Fixing a riveted aircraft skin often means drilling out old rivets and installing new ones – a slower process that’s acceptable because planes spend far less time on the road and more time in the hangar.

Cost & Maintenance

Welding is automated on production lines, reducing labor costs. Riveting, while still automated in aircraft factories, needs more steps and specialized tools, raising the price of each airplane.

For the owner, a welded car means fewer scheduled inspections and lower long‑term maintenance fees. A riveted aircraft must undergo regular non‑destructive testing (NDT) to catch cracks before they grow.

Quick Car Snapshot

| Engine | Mileage | Price | Top Features |

|---|---|---|---|

| 2.3 L Turbo I4 | 28 mpg combined | $35,000 |

|

FAQ

Why do planes still use rivets instead of welding?

Rivets handle the expansion and contraction of thin aluminum skins better, distribute loads over a larger area, and allow easy field repairs without needing heavy welding equipment.

Are welded cars more prone to rust than riveted ones?

Welding can actually seal joints better, reducing moisture entry. Proper coating and corrosion‑proofing keep welded frames very resistant to rust.

Can I replace a rivet with a weld on my car?

In theory you could, but it would require cutting the sheet metal, adding a filler, and re‑welding – a costly process that offers no real benefit over the original design.

What’s your take on welds vs. rivets? Drop a comment below!

Source: Read Official News